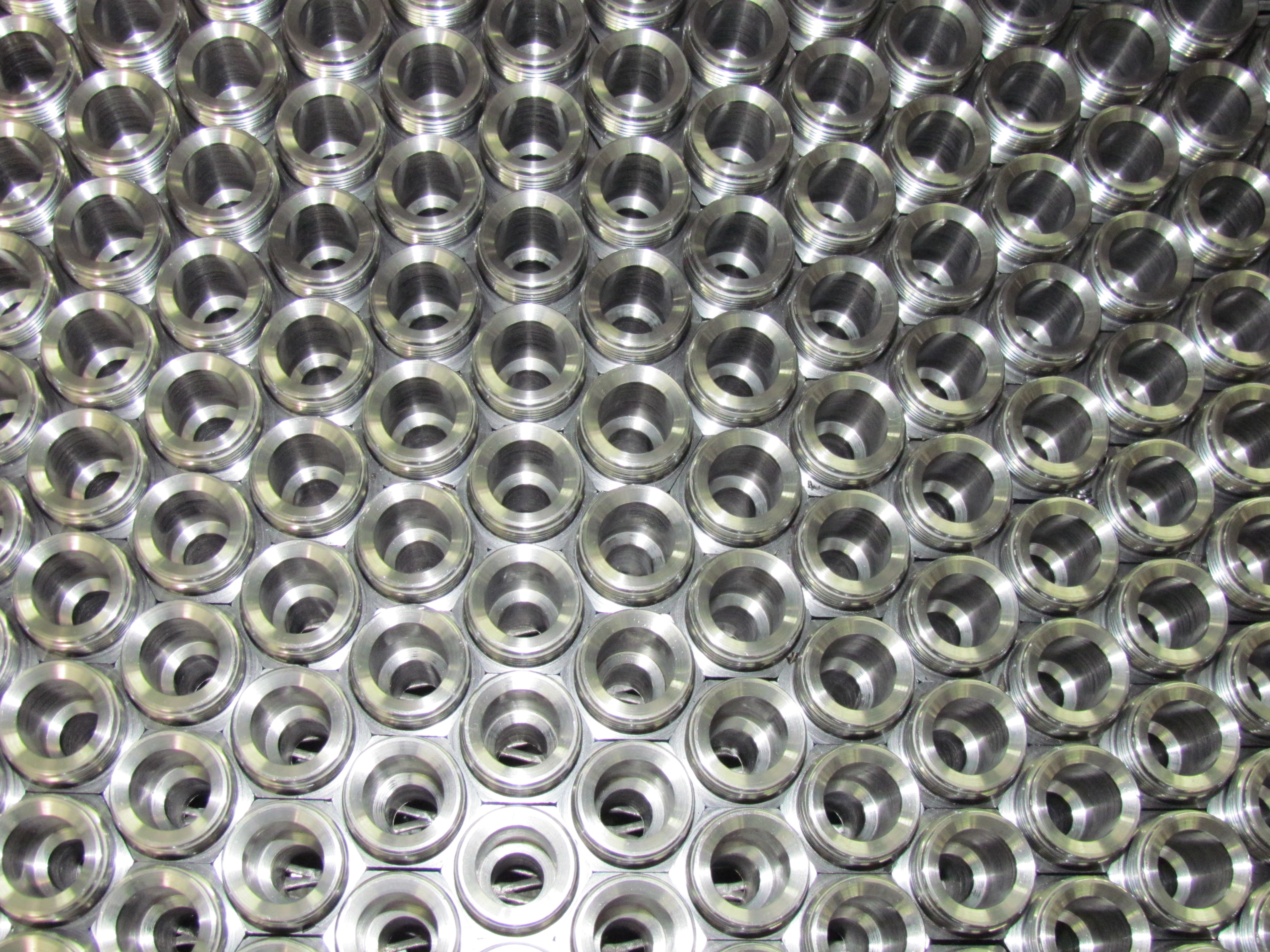

Glendale Heights, IL – Avanti Engineering, Inc., a distinguished family-owned business based in Glendale Heights, Illinois, has once again demonstrated its dedication to delivering excellence in precision machining. Specializing in screw-machined products and CNC-turned parts, the company has invested in a game-changing addition to its repertoire: the iFP KP100 Vacuum Parts Cleaner. This innovative technology promises to revolutionize how machined parts are cleaned and sanitized.

As a Leading machined parts manufacturer, Avanti Engineering, Inc. has constantly pursued excellence by providing premium, precisely machined products at reasonable costs. This commitment is strengthened by the inclusion of the iFP KP100, which guarantees that every machined component leaving its plant is not only accurate but also spotlessly clean and contaminant-free. Regardless of the intricacy or makeup of the machined components, this inventive machine completely cleans and decontaminates them using cutting-edge cleaning methods. It successfully gets rid of particles, emulsions, greases, and oils, leaving the components in perfect shape for usage and installation.

One of the iFP KP100’s distinguishing advantages is its self-contained, environmentally friendly construction. This cutting-edge technology has a small footprint and operates in an airtight manner, minimizing its impact on the environment while providing excellent cleaning results. The machine’s efficiency is unparalleled, allowing Avanti Engineering, Inc. to achieve tight production deadlines with ease.

Beyond its better cleaning skills, the KP100 has several benefits. Because of its cutting-edge technology, consumers will obtain their machined components more quickly. The KP100’s effectiveness fits in perfectly with Avanti Engineering, Inc.’s objective to offer professional and precise services, regardless of order size.

Quality control is the foundation of Avanti Engineering, Inc.’s machining capabilities. The organization follows the demanding ISO 9001 Cert. Quality assurance, guaranteeing that every part of its operations complies with the highest quality norms. The company takes no shortcuts when it comes to quality assurance, from internal audits to statistical process control.

The iFP KP100 Vacuum Parts Cleaner is only one of the many machining services that Avanti Engineering, Inc. provides. Multi-axis CNC and Swiss CNC machining, multi-spindle high-speed screw machines, an internal toolroom with wire EDM services, CAD/CAM consulting and engineering services, certified quality management systems, CNC drilling, tapping, and milling, versatile secondary operations, and light assembly are just a few of its capabilities. Due to the unmatched flexibility this wide variety of services offer, clients may take on projects of any size or complexity.

The company’s investment in the iFP KP100 Vacuum Parts Cleaner is a testament to its allegiance to innovation, quality, and environmental stewardship. With this state-of-the-art machining technology now in its arsenal, the company is prepared to tackle even the most demanding machining tasks, all while ensuring unmatched precision and adherence to environmental responsibility.

Avanti Engineering, Inc. is located at 200 W. Lake Drive, Glendale Heights, IL, 60139, US. For more information about the company and its precision machining services, visit their website or contact their team at 630-260-1333.

Media Contact

Company Name

Avanti Engineering, Inc.

Contact Name

Rocco Bratta

Phone

630-260-1333

Address

200 W. Lake Drive

City

Glendale Heights

State

IL

Postal Code

60139

Country

United States

Website

https://www.avantiengineering.com/

COMTEX_440527892/2737/2023-09-19T14:03:20

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No The Daily News Journal journalist was involved in the writing and production of this article.